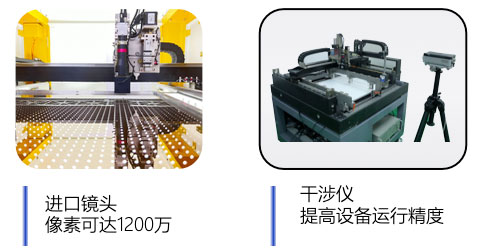

SUNMENTA SVII-K100

SUNMENTA SVII-K100

Automatic Stencil Inspection Machine

This industry-leading fully automated stencil inspection equipment can quickly solve stencil opening and cleaning problems, improve the cleaning process, establish stencil control standards, improve the production management system, replace manual inspection, reduce labor costs, and improve product quality; and solve printing problems such as excessive solder, insufficient solder, and solder bridging from the source.

Process improvement

- Solve problems related to defective incoming materials and cleaning/inspection, and improve the cleaning process.

- Establish steel mesh management standards and improve the production management system.

- Replace manual inspection and improve product quality

- Solve printing problems such as excessive solder, insufficient solder, and solder bridging at the source.

- 01005 and smaller parts are becoming increasingly common, and high-precision testing aligns with future development trends.

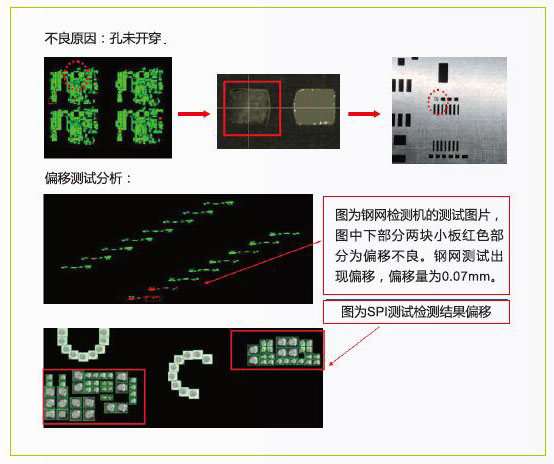

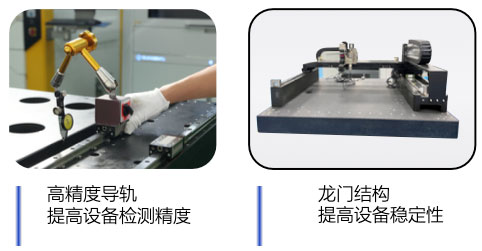

Designed for precision

The high-speed linear motor (magnetic levitation transmission) motion control drive device adopts the Singapore DKM adjustable linear motor drive module, which changes the problem of inaccurate accuracy caused by long-term wear of traditional ball screw transmission. It achieves high precision, maintenance-free operation, and rock-solid durability. The whole machine adopts a marble integrated structure, which is perfectly combined with ergonomics.

video

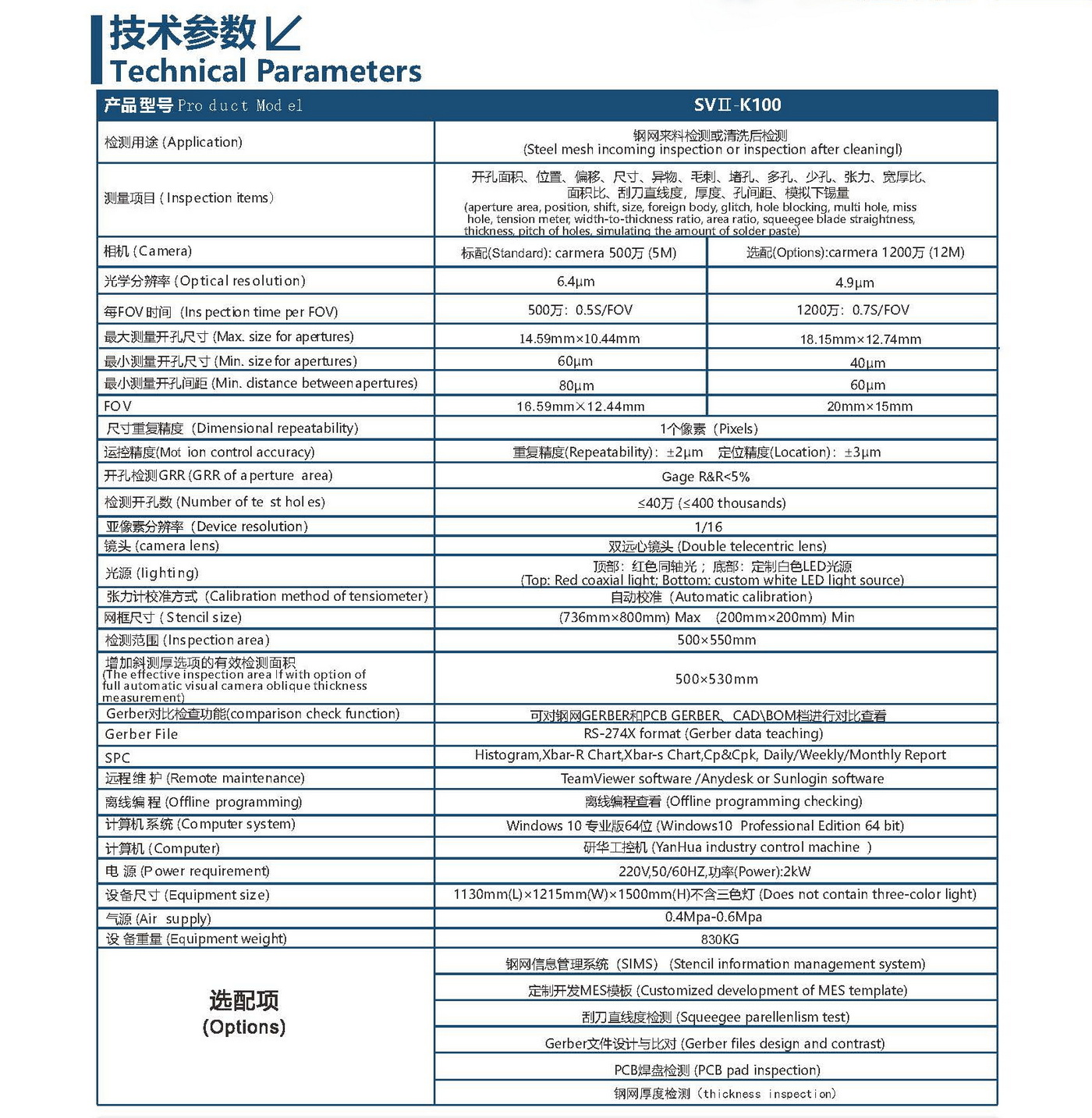

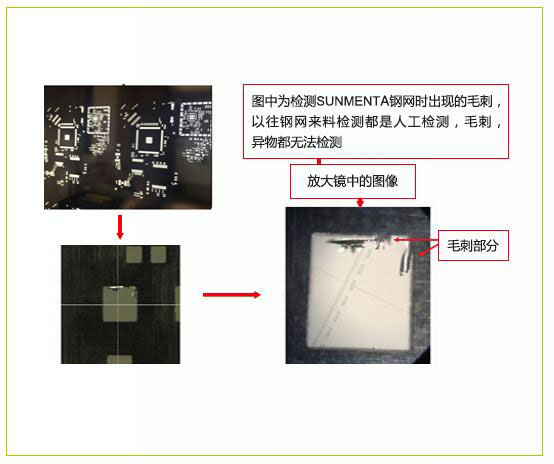

Case Analysis

hardware module

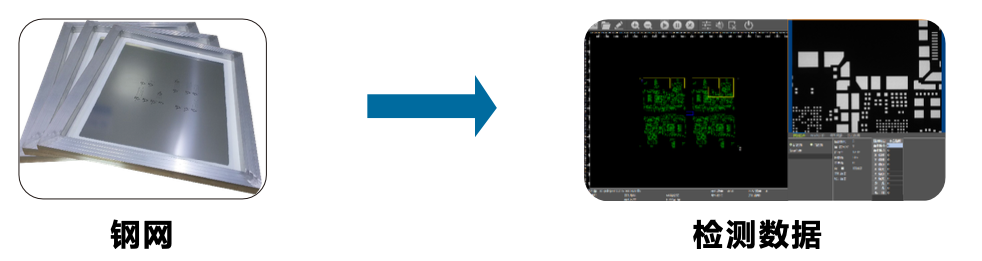

Test materials and data

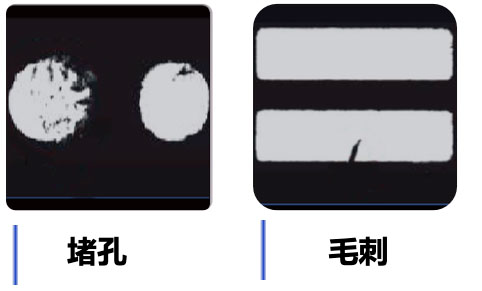

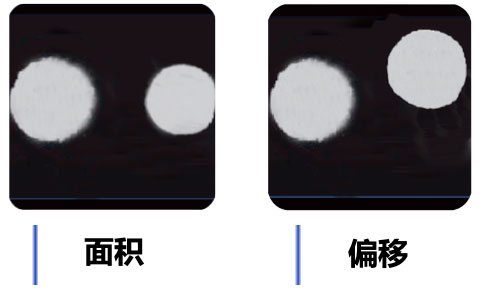

Defect detection graph

Technical features

Import CAD documents; test data can be quickly integrated with SPI for traceability and querying.

Import GERBER data, modular data structure, and instantly measure and view results within 3 minutes.

Rapid steel plate inspection and automatic merging of different SPC analysis structures resolve design specifications issues during steel plate opening processes, quickly guiding customer application.

Inspect the area, location, offset, size, burrs, foreign objects, blockages, insufficient or excessive holes, and tension data of steel plate openings.

The open communication protocol allows for complete data integration with the market's online real-time system, enabling users to view any steel plate number and its usage status at any time.

The world's fastest testing speed, measuring a standard 230*150 PCB in 2 minutes, including viewing the data structure and performing SPC analysis.

SMT inspection equipment improves quality yield and quickly solves slab problems.

Motion control accuracy: Repeatability: ±2μm, Positioning: ±3μm

Number of openings inspected: ≤400,000

Minimum measurement aperture size: 100μm (5M camera)

Frame dimensions: 736mm×736mm (K100), 836mm×836mm (K100S)

Detection range: 500×550mm (K100), 600x800mm (K100S)